Product Description

Company Profiles

-We are a leading gear motor manufacturer

ZHangZhoug Xihu (West Lake) Dis.hai Reducer is a leading manufacturer of gear motor and gearbox.

Since 1991, we have specialized in manufacturing a wide range of gear motor and gear box including:

- helical gear motor

- helical bevel gear motor

- parallel shaft helical gear motor

- helical worm gear motor

- hoist drive

- heavy-duty helical gearbox

- heavy-duty helical bevel gearbox

- gear motor for car parking system

- sprial bevel gearbox

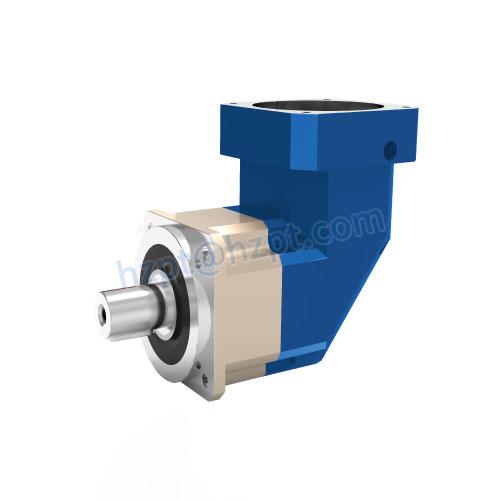

Product Description

DHTC series gear motor for car parking lifting system

The brake adopts flat spring-loaded electromagnetic brake.Its braking rate is 182%, and quick brake time is 0.03s to 0.05s. The fast brake locking value is less than 5cm.With the non-asbestos brake disc dry friction, the overall brake is equipped with titanium cover plate to prevent the damp brake from malfunctioning, which can keep working at full load all day. The input voltage of the fast brake rectifier is 270VAC 50/60Hz, the insulation withstand voltage is 1800VAC 50Hz 1min, and the service life is 1 million times.

The motor adopts aluminum alloy hot high-pressure casting, all copper wire copper enameled wire through deep dipping, insulation class F, protection class IP55, working system S1 operation, moisture-proof and dust-proof fully sealed. Suitable for outdoor working environment +80 ºC to -25 ºC, and not suitable for direct corrosion of objects, the motor power is more than 1.2 times the national standard value.

The special reducer (reduction motor) uses 20CrMnTi gear steel, which is carburized to ensure the hard tooth surface and strength, and is processed by CNC precision grinding to ensure the technical requirements of gear hardness and accuracy. Reducer load operation noise is less than 52dB (A), fully sealed and no oil leakage, maintenance-free and zero-fault design method is adopted, and the service life is 30 years.

Product Show

Product Specification

Package

Plastic bag + wooden carton

Certificate

FAQ

Q: Can you print other colors?

Yes. Customized color can be printed on the gear motor according to your requirements.

Q: Is that factory price?

Yes. We assure you all prices are based on factory.

Q: What is the life span? what is the guarantee

The lifespan of gear motor can reach 5-20 years depending on different working conditions .The guarantee time is 1 year after delivery.

Q: What documents are available?

A full range documents including structural drawings, packing list, installation manual and relative certificates can be provided. Moreover, customs declaration is provided. We provide one-stop service for you.

Q: Is it able to customized?

yes, we could re-design and produce the gear motor as your requirements if the quantity is large.

| Application: | Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

Examples of Vehicles and Equipment Using 90 Degree Gearboxes

90 degree gearboxes are commonly used in various vehicles and equipment where a change in direction of power transmission is required. Here are some examples:

- Automobiles: Many vehicles use 90 degree gearboxes to transmit power from the engine to the wheels, especially in front-wheel drive configurations where the engine is mounted transversely.

- Construction Machinery: Equipment like excavators and loaders use 90 degree gearboxes to change the direction of power in hydraulic systems that control movements.

- Agricultural Equipment: Tractors and combines often employ 90 degree gearboxes to transfer power from the engine to various components like the drivetrain and attachments.

- Marine Applications: Boats and ships use 90 degree gearboxes to change the direction of propulsion power from the engine to the propellers.

- Industrial Machinery: Many industrial machines use 90 degree gearboxes to transmit power in different directions, enabling complex movements and operations.

- Printing Presses: Printing presses often use 90 degree gearboxes to change the direction of power transmission between different sections of the machine.

- Textile Machinery: Textile manufacturing equipment may use 90 degree gearboxes to change the direction of power for various processes.

- Material Handling Equipment: Conveyor systems and other material handling equipment use 90 degree gearboxes for changing the direction of movement.

- Robotics: Robotic arms and mechanisms often utilize 90 degree gearboxes to achieve precise movements and positioning.

- Food Processing Equipment: Machinery used in food processing may use 90 degree gearboxes to change the direction of power transmission in various stages of production.

These examples highlight the versatility and importance of 90 degree gearboxes in a wide range of applications across different industries.

Impact of a 90 Degree Gearbox on System Efficiency

A 90 degree gearbox can have both positive and negative impacts on the overall efficiency of a system:

- Positive Impact: In systems where space constraints or directional changes are critical, a 90 degree gearbox enables the transmission of power and torque at a right angle, allowing for compact designs and efficient use of available space.

- Negative Impact: However, a 90 degree gearbox can also introduce efficiency losses due to several factors:

- Friction: The additional gear meshing in a 90 degree gearbox introduces more points of contact and friction, leading to energy loss in the form of heat and decreased efficiency.

- Direction Changes: Changing the direction of power transmission requires additional gear engagement and disengagement, leading to mechanical inefficiencies and energy losses.

- Gear Design: The gear profiles and design used in 90 degree gearboxes may not be as optimized for efficiency as those in straight-through gearboxes, resulting in more energy loss.

It's important to assess the specific requirements of the system and the trade-offs between space savings and efficiency. In some cases, the benefits of using a 90 degree gearbox may outweigh the efficiency losses, while in others, alternative gearbox designs may be more suitable to achieve higher overall system efficiency.

Applications of a 90 Degree Gearbox

A 90 degree gearbox, also known as a right-angle gearbox, finds diverse applications across various industries due to its ability to change the direction of rotational motion by 90 degrees. Some common applications include:

- Automotive Industry: 90 degree gearboxes are used in automotive drivetrains to transfer power from the engine to the wheels, especially in front-wheel drive configurations.

- Conveyor Systems: These gearboxes are employed in conveyor systems to change the direction of material flow at right angles, allowing efficient material handling and sorting.

- Printing Machinery: In printing presses, 90 degree gearboxes enable the smooth transfer of motion from the main motor to various rollers and components, ensuring accurate paper movement.

- Machine Tools: They are used in machine tools such as milling machines and lathes to transmit power at right angles, enabling precise machining operations.

- Robotics: 90 degree gearboxes play a crucial role in robotic arms, allowing joints to move and rotate in different directions while maintaining a compact design.

- Marine Applications: They are used in marine propulsion systems to change the direction of power transmission from the engine to the propeller shaft.

- Industrial Equipment: These gearboxes are utilized in various industrial equipment like pumps, compressors, and generators to transmit power efficiently at right angles.

- Medical Equipment: They find use in medical devices and equipment that require compact design and efficient power transmission at different angles.

The versatility of 90 degree gearboxes makes them a valuable component in applications that require changing the direction of motion while maintaining space efficiency and power transmission integrity.

editor by CX 2023-09-06